Description

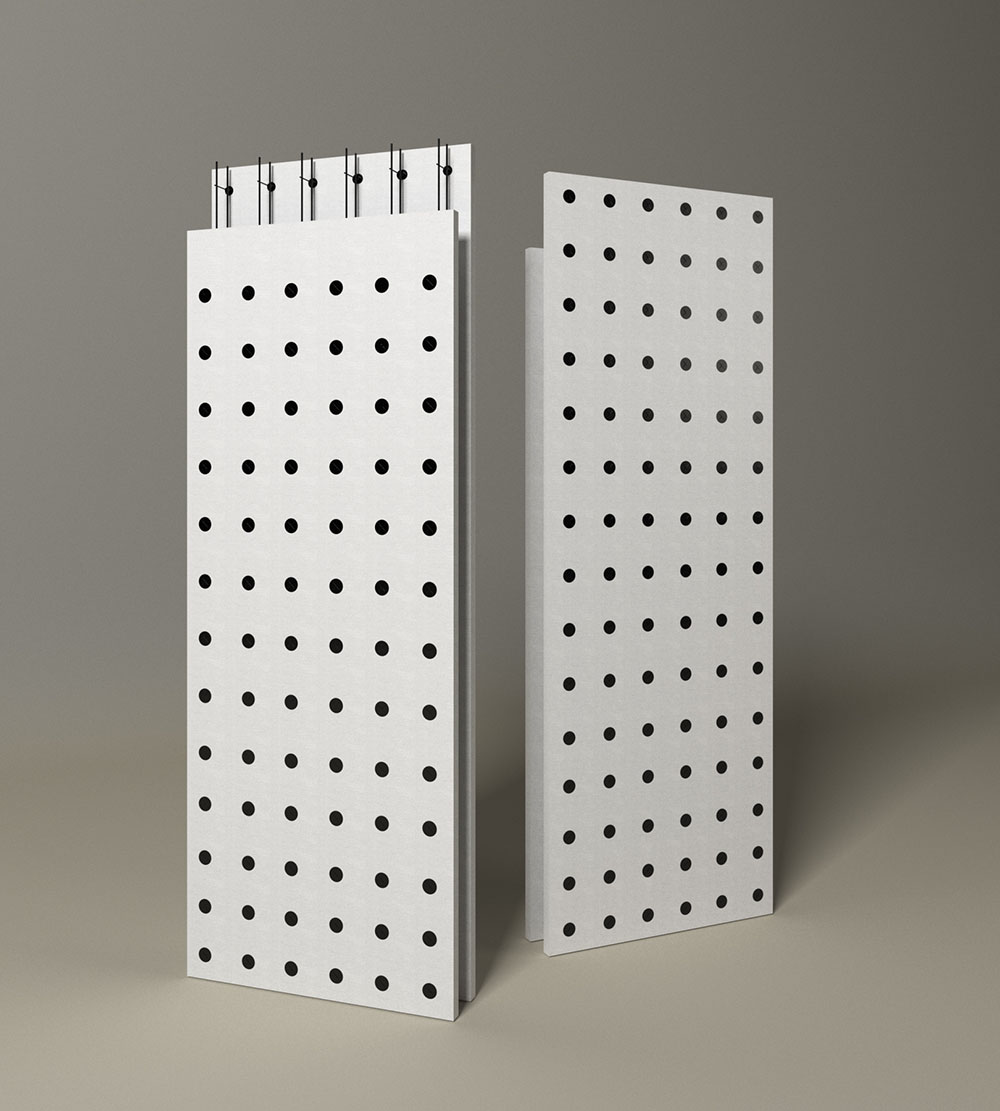

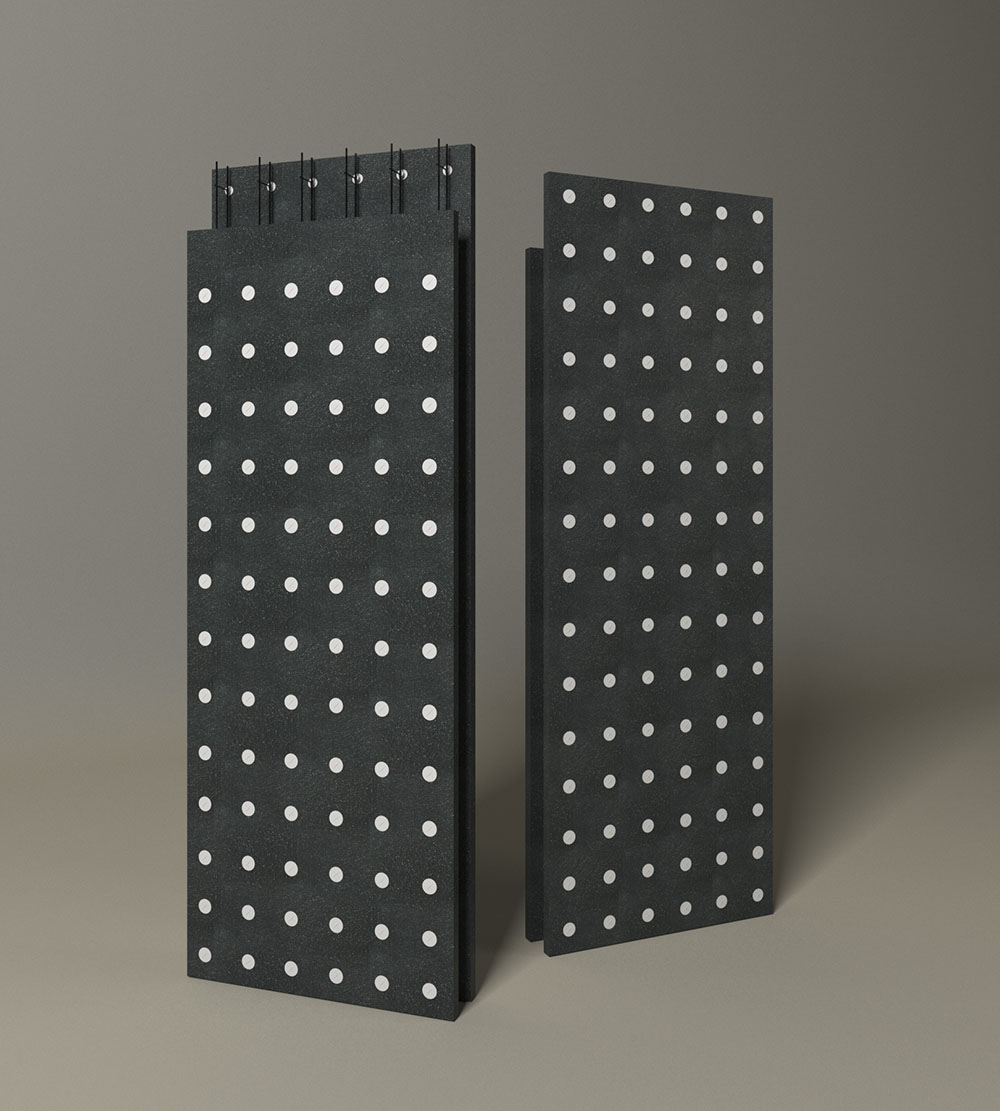

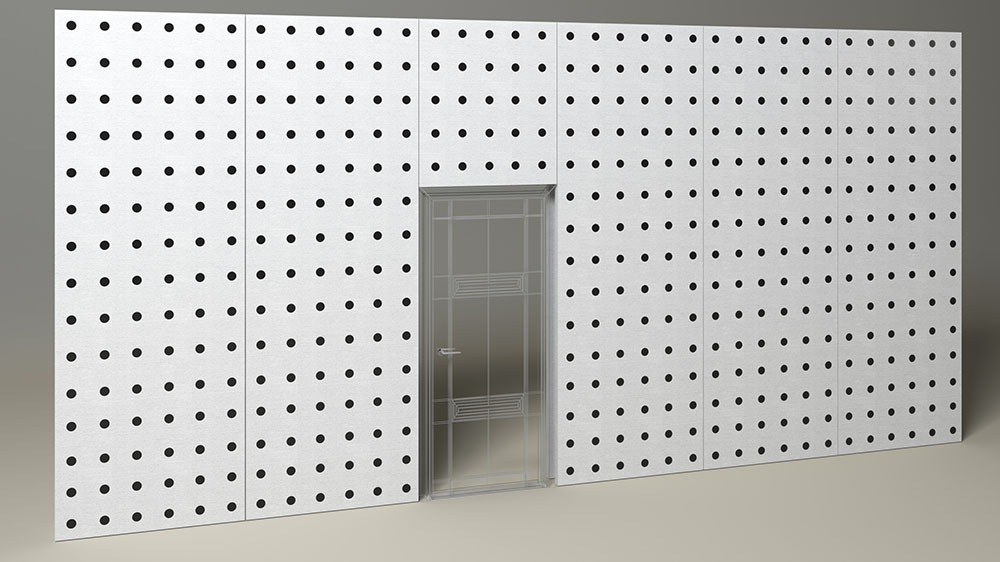

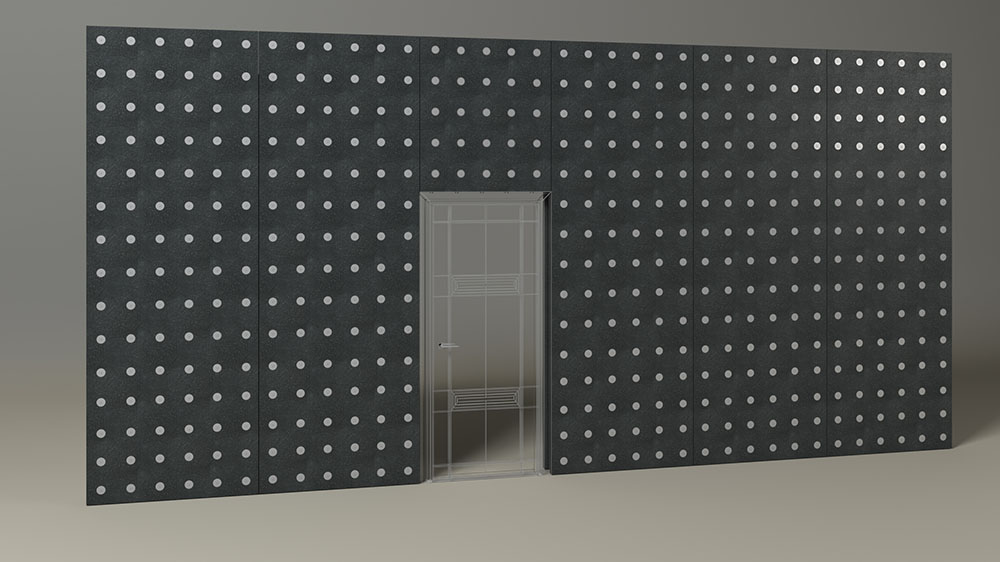

Insulated Concrete Formwork (ICF) System for Walls (E-Wall):

Insulated Concrete Formwork (ICF) for wall, also referred to as E-Wall, is an innovative construction technique that’s reshaping the traditional building sector. It consists of a load-bearing wall element made up of two expanded polystyrene (EPS) boards, held together by vertical steel ladders and plastic screw caps. This structure serves as both the building’s exterior wall and insulation, providing a sturdy, energy-efficient solution for modern-day constructions.

Advantages of the ICF Systems for Walls (E-Wall):

ICF systems offer many advantages, which solidifying their position as a competitive choice in the construction industry.

1. Thermal Insulation: ICF walls provide superior thermal insulation, thereby reducing the need for additional heating and cooling systems, and potentially saving up to 40% on AC electricity bills.

2. Acoustic Insulation: The EPS boards effectively dampen sound, providing excellent acoustic insulation.

3. Fire Retardant: ICF walls have a high fire resistance rating, enhancing the safety of the buildings they’re used in.

4. Cost-Effective: Despite the high-quality features, the cost of ICF systems remains competitive compared to other new construction technologies.

5. Durability: They are resistant to earthquakes and natural disasters, ensuring long-lasting stability. Furthermore, their lifespan exceeds 50 years, making them a sustainable choice.

6. Design Flexibility: ICF systems for walls can be customized to meet any design request, providing architects with a high degree of creative freedom.

7. Quick Installation: The simplicity of the ICF system allows for fast, efficient installation, reducing construction timelines.

8. No Full Shuttering: This feature simplifies the construction process, making it more efficient.

9. Zero Thermal Bridge: When used with E-Deck, ICF system for walls can offer a zero thermal bridge, further enhancing their energy efficiency.

10. Versatile Finishing: They can accommodate a wide range of finishes, offering flexibility in design and aesthetics.