Description

EPS (Foam) Wall Cladding

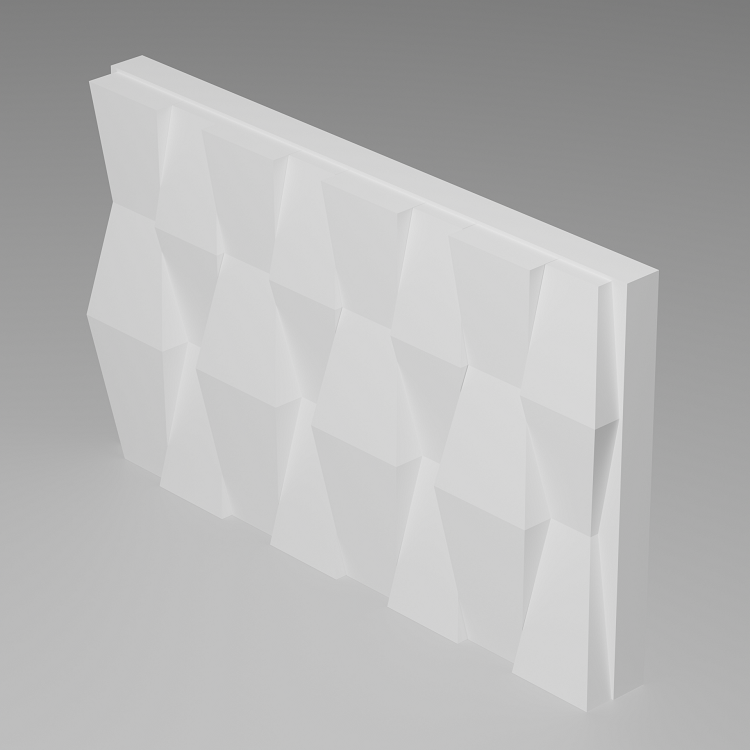

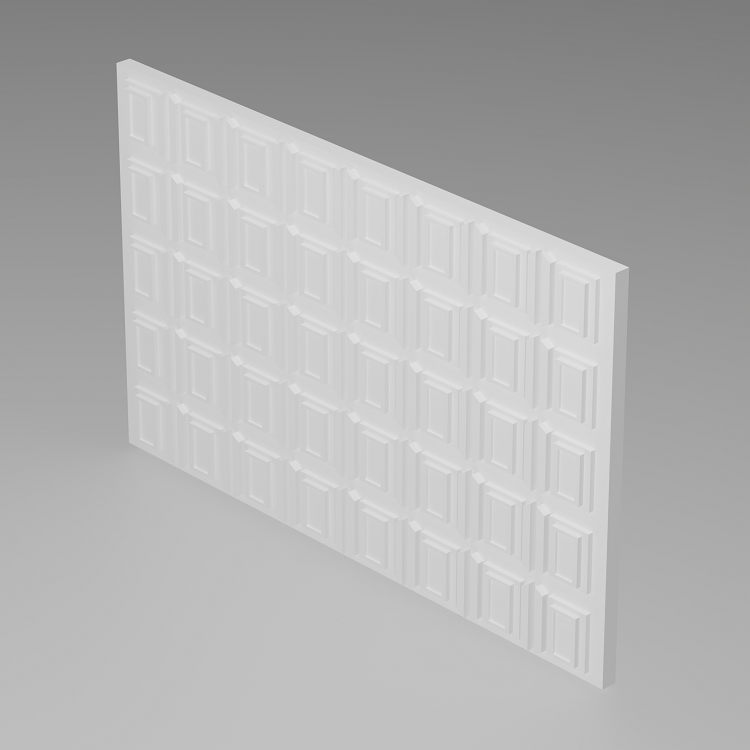

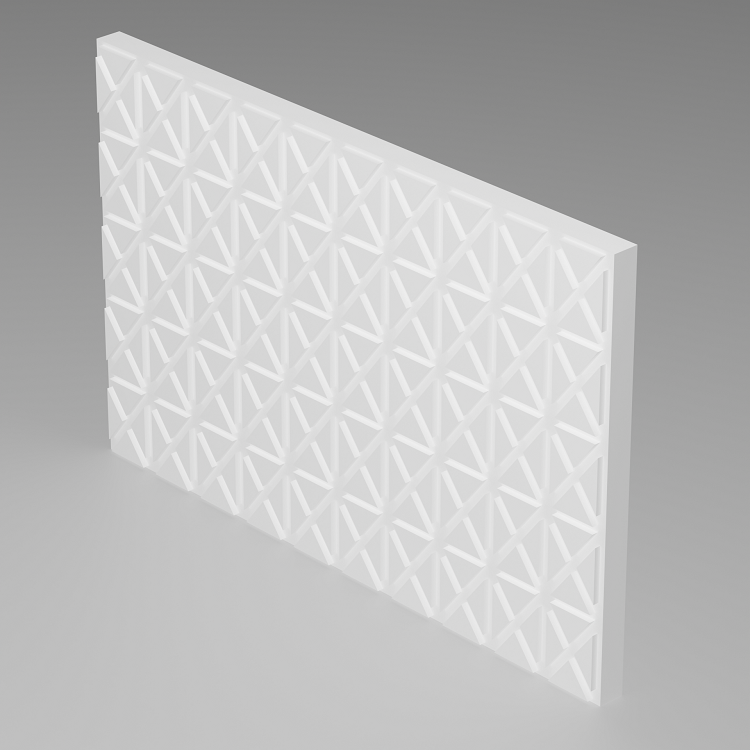

EPS (Expanded Polystyrene) or foam decorative wall cladding is a popular choice for enhancing the visual appeal of interior and exterior spaces. It involves the use of panels made from expanded polystyrene or foam, which are designed to mimic the appearance of various materials like brick, stone and wood or any decorative design types. These lightweight panels are highly versatile and offer numerous benefits when it comes to decorative wall cladding applications.

The Advantages of Using EPS or Foam in Decorative Wall Cladding:

1. Lightweight: One of the significant advantages of EPS or foam decorative wall cladding is its lightweight nature. The panels are easy to handle and install, reducing the need for heavy machinery and labour-intensive processes. This makes it a cost-effective option for both residential and commercial projects.

2. Insulation Properties: EPS foam has excellent insulation properties, providing thermal efficiency to buildings. When used as decorative wall cladding, EPS panels can enhance the overall energy efficiency of a structure by reducing heat transfer and minimizing energy consumption for heating and cooling.

3. Durability: Despite their lightweight composition, EPS or foam panels are durable and long-lasting. They are resistant to moisture, rot, and insect damage, ensuring that the cladding maintains its aesthetic appeal for an extended period. This durability reduces maintenance requirements and associated costs.

Comparison Between EPS or Foam and Other Materials Used in Decorative Wall Cladding:

When compared to traditional materials like brick, stone, or wood, foam decorative wall cladding offers several advantages. Unlike heavier materials, EPS panels are easier to handle and install, reducing construction time and costs. Additionally, EPS cladding provides better insulation properties and is less susceptible to damage from moisture or insects.

Installation Process:

First, the existing wall surface is prepared by cleaning it and ensuring it is smooth. The panels are then cut to the desired size and shape, and an adhesive is applied to the back of each panel. The panels are then attached to the wall surface, ensuring proper alignment and secure attachment. Finally, any necessary finishing touches, such as caulking or painting, are applied to achieve a seamless appearance.