Description

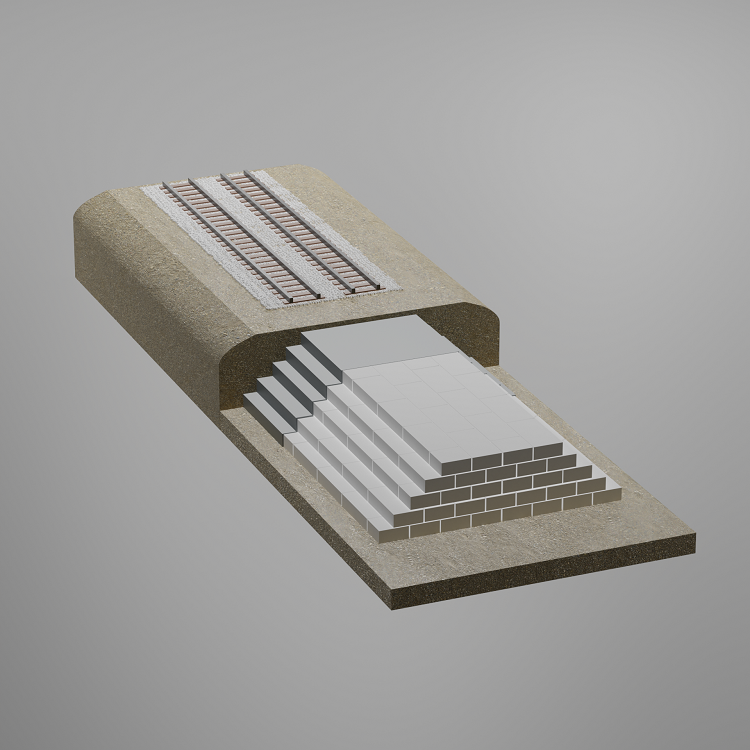

Geofoam for Railway

Geofoam, a lightweight fill material, has emerged as a viable solution for constructing railway embankments with minimal stress on underlying soils. With its robust strength and ability to support heavy loads, Geofoam offers numerous advantages in terms of stability, durability, and environmental impact.

Geofoam for Railway Benefits

One of the key benefits of using Geofoam in railway application is its lightweight nature. Compared to traditional fill materials such as soil or rock, Geofoam is significantly lighter, reducing the overall load imposed on the underlying soils. This characteristic is particularly crucial when constructing railway embankments, as excessive stress on the ground can lead to settlement issues and structural instability. By using Geofoam, engineers can mitigate these concerns, ensuring a stable and long-lasting railway structure.

Furthermore, Geofoam’s strength is another advantage that makes it an ideal choice for railway construction. Despite its lightweight properties, Geofoam exhibits remarkable strength and load-bearing capacity. It can effectively support the heavy loads imposed by trains, tracks, and other railway infrastructure. This strength ensures that the embankment remains intact and can withstand the dynamic forces associated with railway operations.

The use of Geofoam also minimizes adverse impacts on the existing ground. Traditional fill materials often require extensive excavation and compaction, leading to disturbances in the surrounding environment. In contrast, Geofoam can be easily installed and does not require compaction, reducing the need for disruptive construction activities. This not only saves time and resources but also minimizes the environmental footprint of the project.

Moreover, the durability of Geofoam contributes to its appeal for railway embankment construction. Geofoam is resistant to moisture, chemicals, and biological degradation, ensuring its long-term performance. It does not settle or decay over time, maintaining its structural integrity and functionality. This durability translates into reduced maintenance costs and a longer lifespan for the railway infrastructure.