Description

Expanded Polystyrene (EPS) Sheets

Expanded Polystyrene (EPS) sheets, known also as foam sheets, are lightweight and rigid materials widely used in a range of industries and applications. EPS sheets are derived from polystyrene, a thermoplastic polymer that undergoes an expansion process to create a cellular structure, resulting in a highly insulating and versatile material.

Expanded Polystyrene (EPS) Sheets’ Benefits

EPS sheets offer numerous benefits that contribute to their popularity across different sectors. Firstly, their lightweight nature makes them easy to handle, transport, and install, reducing labour and transportation costs. Additionally, EPS sheets provide exceptional thermal insulation properties, which help to regulate temperature and energy consumption in various environments.

Moreover, EPS sheets exhibit excellent impact resistance, making them an ideal choice for protective packaging solutions. The foam structure of EPS sheets absorbs shock and protects fragile or sensitive items during transportation or storage, preventing damage and minimizing losses. This feature is particularly valuable for industries such as electronics, consumer goods, and pharmaceuticals.

EPS sheets are also moisture resistant, making them suitable for applications in damp or humid environments. They do not absorb water, ensuring their structural integrity and preventing the growth of mold or mildew. This moisture resistance makes EPS sheets ideal for use in areas such as basements, crawl spaces, and swimming pool insulation.

Expanded Polystyrene (EPS) Sheets’ Benefits

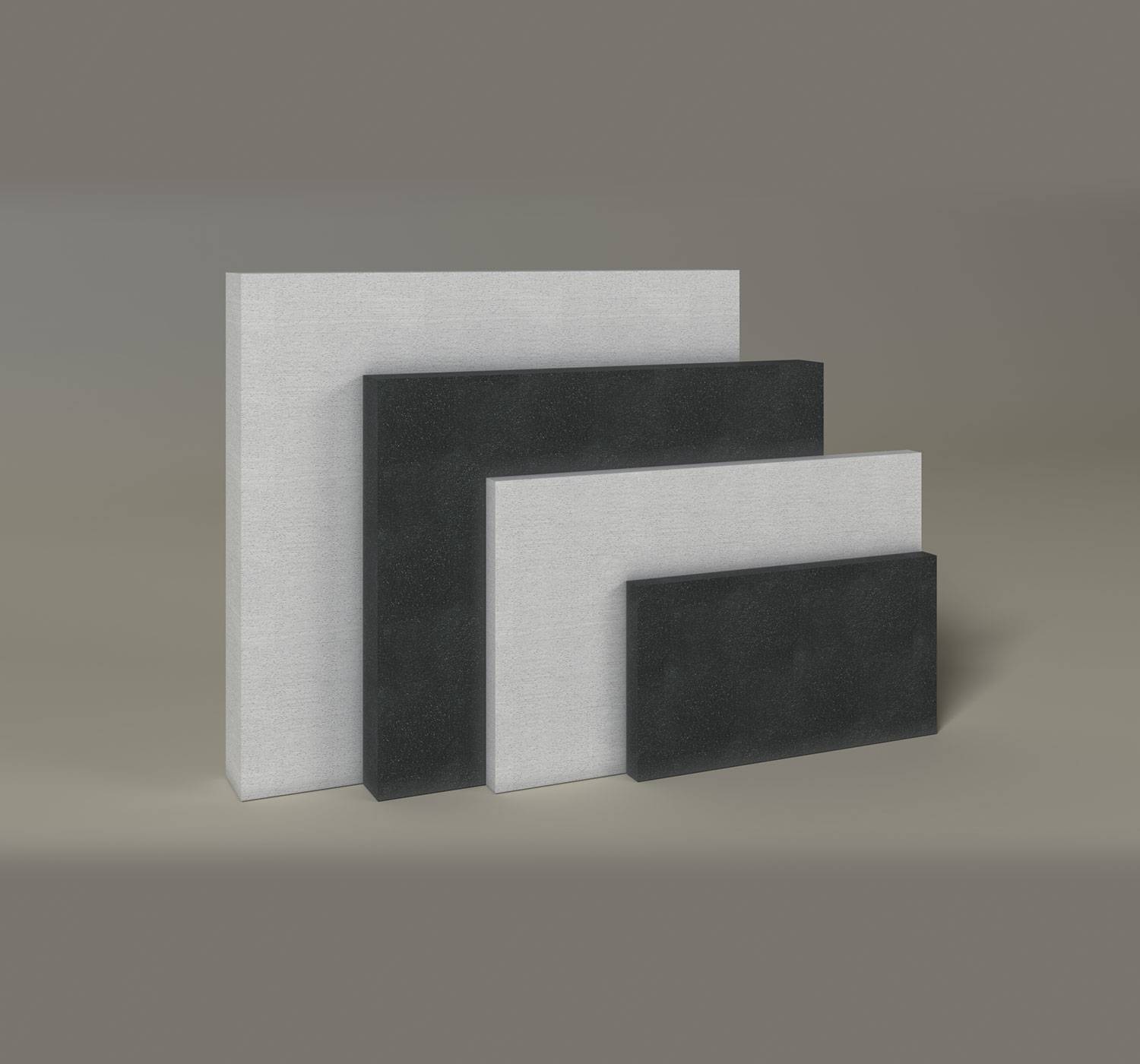

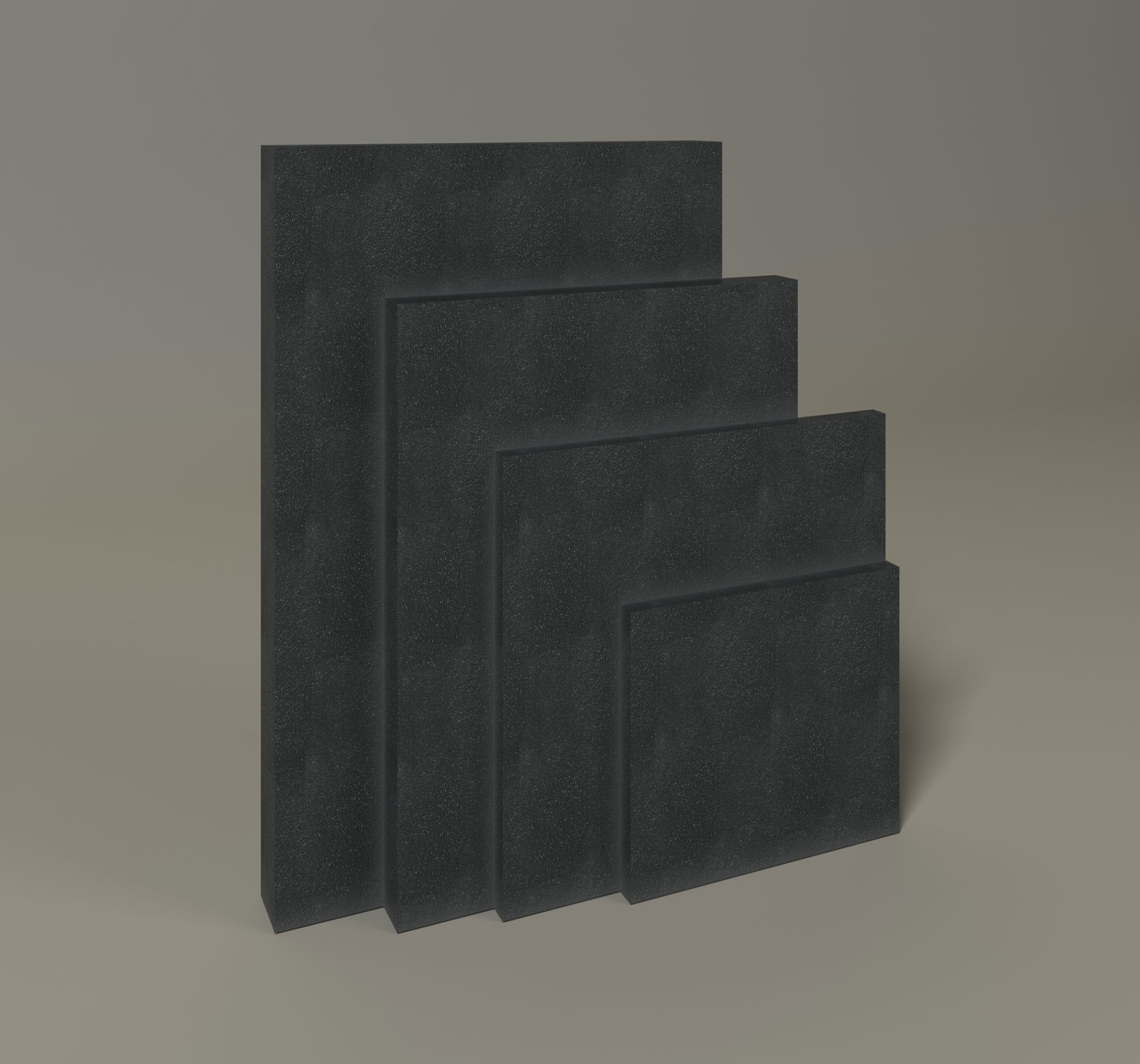

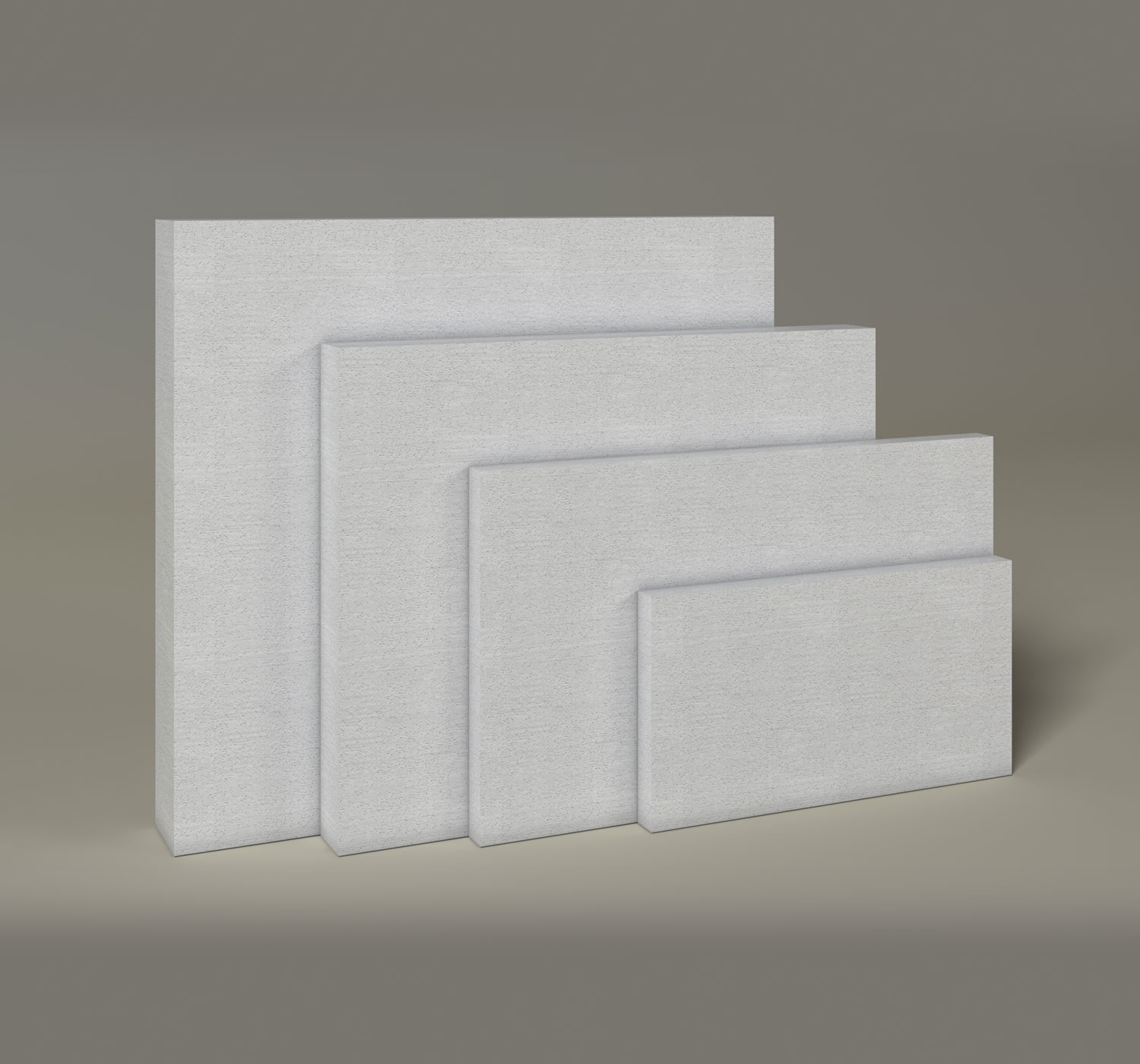

There are two types of Expanded Polystyrene sheets which are white EPS and Grey EPS. One crucial difference between white EPS and grey EPS is the addition of graphite to the mixture in grey EPS. This addition significantly improves the performance of the polystyrene. In fact, with just a thickness of 90mm in grey EPS, you can achieve the same level of performance as a 120mm block of white EPS. This enhancement is a remarkable improvement for such a small change in the mixture, making grey EPS highly efficient in terms of insulation performance.

In conclusion, EPS sheets, available in both white and grey variants, are versatile materials with a wide range of applications across various industries. The addition of graphite in grey EPS significantly enhances its insulation performance, allowing for thinner sheets to achieve the same level of efficiency as thicker white EPS blocks. Whether it is in construction, packaging, automotive, or other specialized uses, EPS sheets provide a cost-effective and reliable solution for insulation, protection, and more.