Description

Geofoam for Void Formers and Fillers

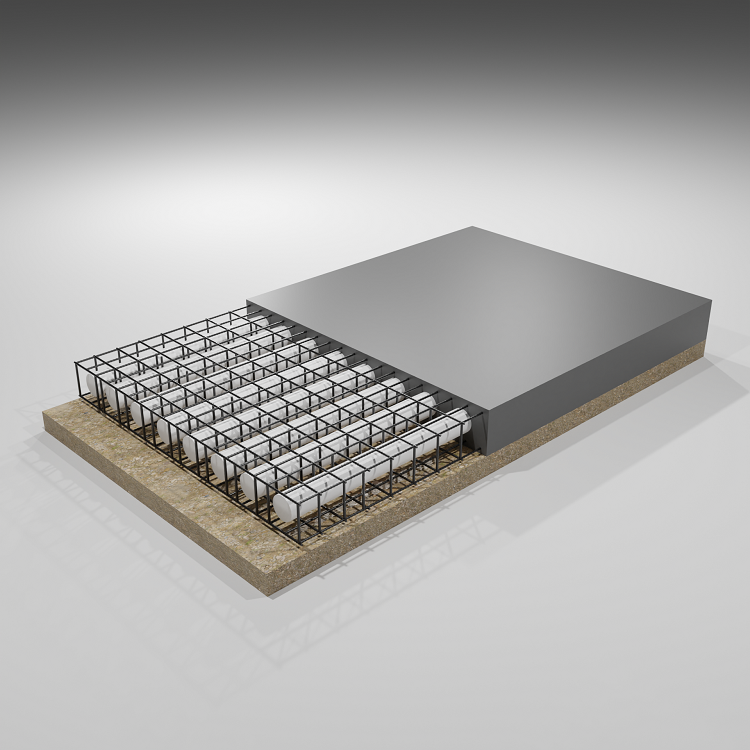

Geofoam, a lightweight, expanded polystyrene (EPS) material, has emerged as a valuable solution in the construction industry know as Geofoam for void formers and filler. With its unique properties and benefits, geofoam offers a range of applications that improve construction efficiency and sustainability.

As a void former, geofoam is used to create empty spaces or voids within structures. It replaces traditional materials such as soil or gravel, reducing the weight and stress on the underlying soils. This is particularly beneficial in applications like road embankments, bridge approaches, and retaining walls, where excessive loads can be problematic. Geofoam’s lightweight nature minimizes settlement and improves overall stability.

Geofoam for Void Formers and Fillers Benefits

One of the key advantages of using geofoam as a filler is its exceptional compressive strength. Despite its lightweight composition, it can support heavy loads without significant deformation. This property is crucial in applications where strong support is required, such as beneath airport runways or storage tanks. By using geofoam, construction projects can achieve the desired structural integrity while reducing material and labour costs.

Geofoam’s durability is another significant advantage. It is resistant to moisture, chemicals, and freeze-thaw cycles, ensuring long-term performance in various environmental conditions. The material does not degrade over time, maintaining its structural integrity and functionality.

In addition to these benefits, geofoam is also an eco-friendly solution. It is 100% recyclable and does not release harmful gases or chemicals during its lifespan. By incorporating geofoam as a void former and filler, construction projects can reduce their environmental impact and contribute to sustainable building practices.

Geofoam for Void Formers and Fillers’ Installation Process

The installation process for geofoam for void formers and fillers is relatively straightforward. The material is supplied in large, pre-formed blocks or panels that can be easily transported and placed on-site. The blocks are cut to the required size and shape using standard construction tools. Due to its lightweight nature, geofoam can be handled and maneuverer by a smaller workforce, reducing labour requirements and improving overall project timelines.